Food Microbiology and Food Safety

K-State's Food Microbiology program and Food Safety and Defense programs address issues with quality and safety of food products from farm-to-fork. Pre-harvest research at the farm level improves the microbial status of final products. Processing technologies such as irradiation, thermal treatments, chemical washing, and Steam Pasteurization are investigated for food decontamination purposes.

K-State's Food Microbiology program and Food Safety and Defense programs address issues with quality and safety of food products from farm-to-fork. Pre-harvest research at the farm level improves the microbial status of final products. Processing technologies such as irradiation, thermal treatments, chemical washing, and Steam Pasteurization are investigated for food decontamination purposes.

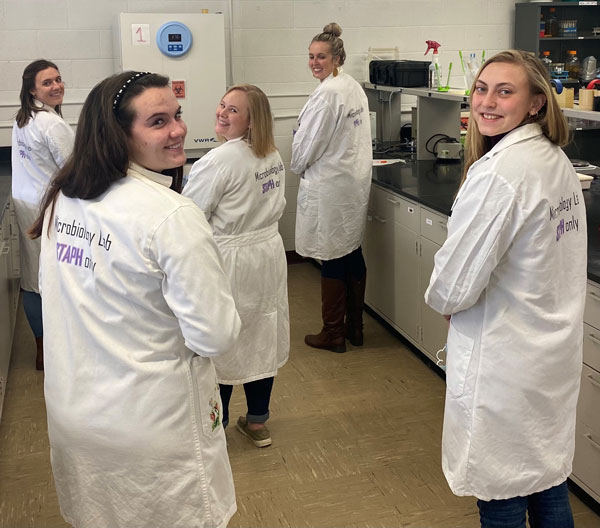

K-State is internationally recognized for its development of rapid and automated microbial detection systems and training programs. Students gain practical training in concepts such as Hazard Analysis and Critical Control Point (HACCP) programs and risk assessment/management that prepare them for careers in the industry.